MADE IN GERMANY

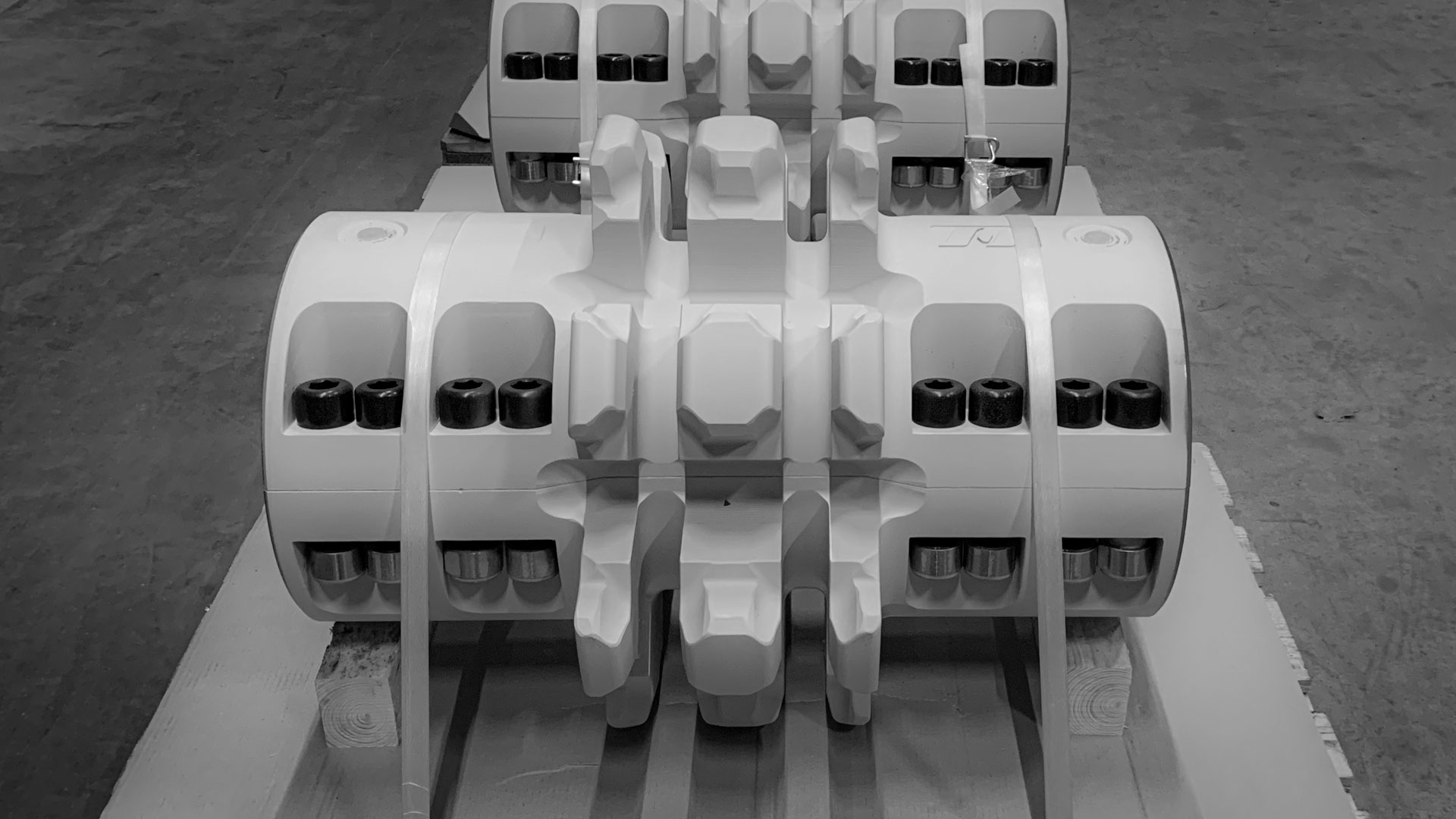

SPROCKETS

Our core competence with the most extensive experience are Sprockets for Mining, wether it is for hard rock, ores or other minerals. When it comes to manufacture sprockets out of a solid billet, there is no company else which has this massive diversity and know-how for customized sprockets in consideration of the scope of application, geometry and of course compatibility with chains. NEUHAUS Sprockets are manufactured to the highest quality level and designed to fit the customers‘ conditions at the mine site. Whereas serial produced sprockets are mainly made from a high degree of standardization the important properties are often neglected. Therefore, we develop sprockets different for each customer because each customer is faced with different conditions. Considering the chemical and structural composition of the material to be conveyed, the location of the mine site and the integration in the higher-level of the whole conveying system requires an individual product and not a standard catalogue item. Also aligned to the geometry of the specific chain in use, we develop a perfect pitched pair.

Sprockets for Round Steel Chains Size 60+

Track Wheels &

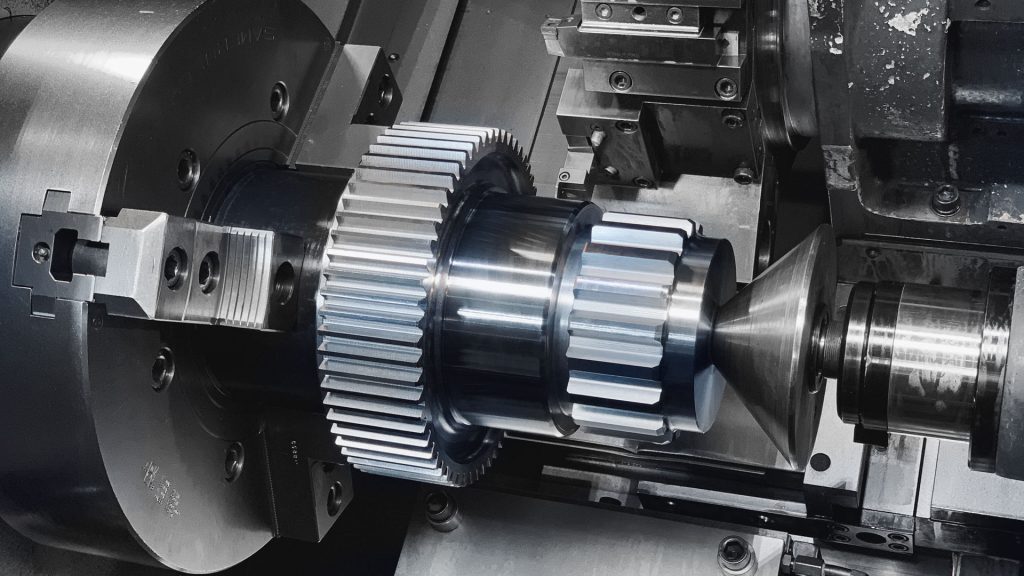

Gear Sprockets

Special

Sprockets

OUR ADVANTAGES

40 YEARS of EXPERIENCE

Manufacturing a sprocket is based on long-lasting experience to create the perfect product. Selecting the right material, processing an optimal tooth geometry for a smooth pitch between chain and flight bar, as well as mastering special heat treatments ensures maximum quality for maximum life. We are supplying and also consulting customers with our know-how and products throughout a wide range of sprockets beginning with small sprockets for chain size 18mm up to 60mm and more.

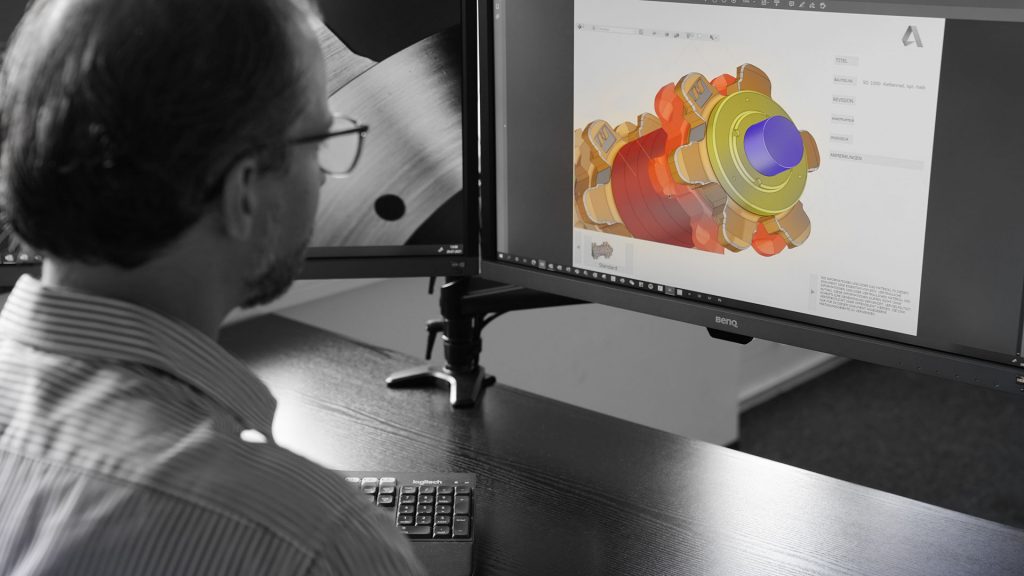

INDIVIDUAL GEOMETRY

Over years we have developed our NCC-Shape which ensures a smooth transition between sprocket and chain. This pattern can be modified and applied on every different chain type and brand to verify that the chain smoothly slides in and out of the sprocket. We have a broad range of advantages which can be implemented to your products such as material type, heat treatment and resistance to wear, therefore we must learn about the concrete situation, means the conditions and requirements at the mine site. This approach leads to a maximum degree of customization.

High quality Materials

Best performance requires highest quality standards beginning with the selection of the right material for individual applications. We will be happy to assist you with the right choice of material and its related heat treatment options for maximum performance. One major quality feature of NEUHAUS Sprockets is that we only use forged solid billets instead of cast material. Thus, we are able to produce also smaller lots of unique sprockets.

100% Inhouse Processing

As a one-stop-shop system supplier we provide services to the full extend. Beginning with consultation based on our great experience we prepare customized designs and constructions, sourcing the best material and ensure a production in our modern industry 4.0 manufacturing facilities with 100% of vertical integration. The completion and test runs of assemblies are done by trained and qualified skilled workers with great job experience and professional equipped infrastructure.

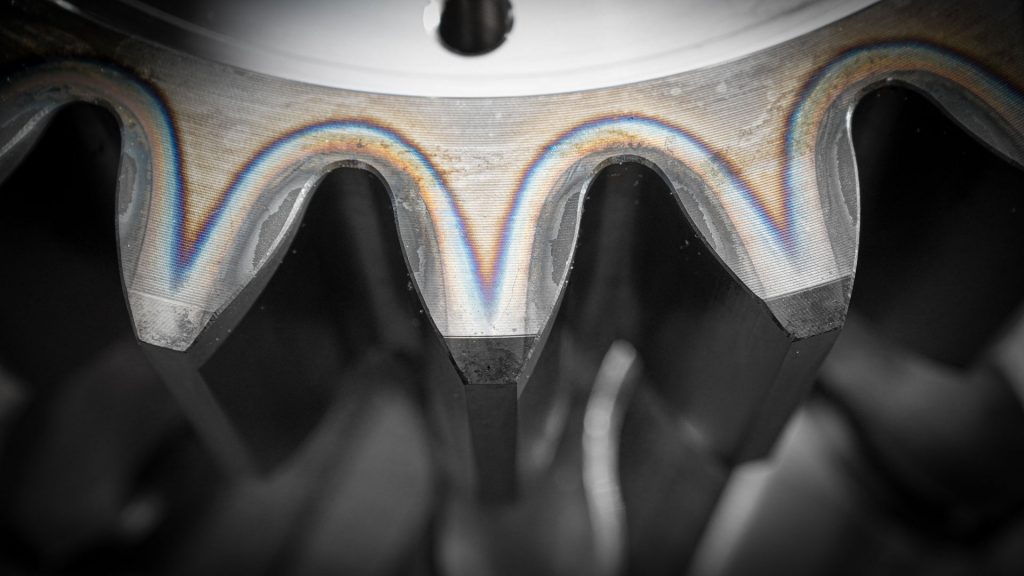

Perfection in Heat-Treatment

Within the hardening process the steels‘ structure transforms from austenite into martensite by heating and quenching. As the steel changes its properties to a hard and brittle but finer structure, it needs to get heat treated again to gain more tensile strength and toughness. Afterwards, the so-called tempering, the hardness will be reduced and the required properties such as hardness, tensile strength and toughness of the steel will be set. Therefore the steel is heated again to create the desired hardness in use, depending on the alloy content and desired properties.

SYSTEM INTEGRATION

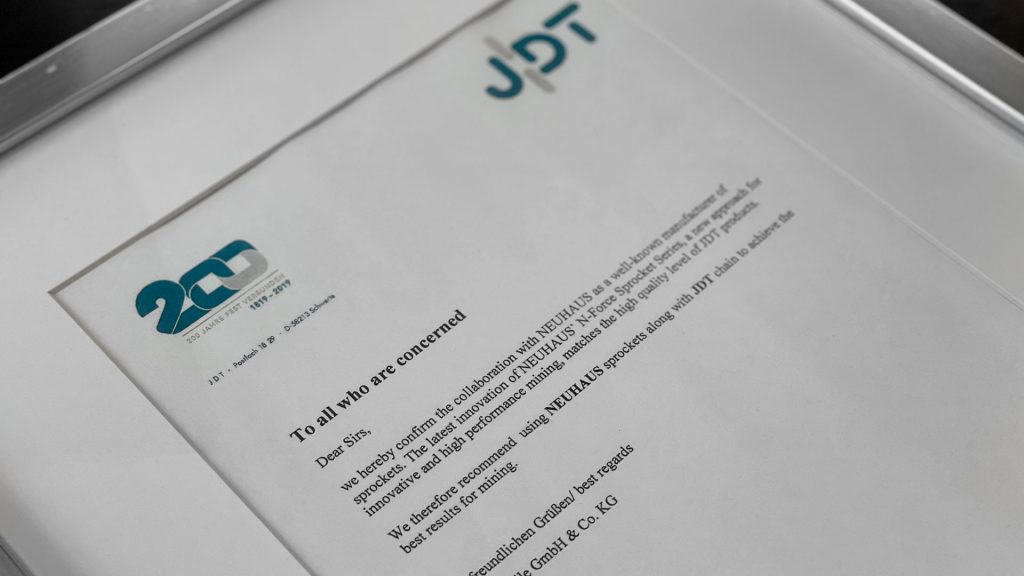

NEUHAUS provides smart solutions and innovative products for chain conveying systems in collaboration with JDT chains. With our focus on customization, customers can choose between adapting our products to existing systems or collaborating with us to develop new projects.

Best Results

The N-Force Sprocket Disc Series which is a new way of manufacturing sprockets regarding material and heat treatment is our high end solution for highest requirements and maximum service life. The sprockets have a core hardness up to max. 1200N/mm² and the hardness of the teeth is up to max. 63HRc. Although the hardness is very high the sprocket is still characterized by great toughness which is important. The N-Force Sprocket Series is available starting with chain size 48mm up to 60+mm.